Drop in Moshi replacement now Available In Store!

I purchased one of these laser cutters from eBay, with full knowledge that the provided software (Moshi Draw) was not going to be suitable for my purposes.

What I hadn't realised is that you can't run the supplied (dongle locked) software under VirtualBox. Having made the switch to Linux years ago, I had no intention of using a dedicated Windows machine!

Optional features:

• Coolant temperature monitoring (DS18B20 1-wire sensor)

• Analogue Joystick control to set the origin

• LCD Display of coordinates and Power / PPI (Nokia 5110 LCD)

• Networked backend using R-Pi / BeagleBone

This drop in replacement for the Moshi Board enables you to use the full potential of your 40W machine from Linux / Windows / Mac.

Standard Features:

• GCode Control via USB Serial

• PWM Power Control

• Raster (Image) Engraving

• PPI (Pulses Per Inch) Speed de-coupled intensity control

• Open Source (GPL) Firmware

• DSP Like Performance

• 2x Open Drain Outputs (e.g. Air Assist)

• 5V Powered USB port

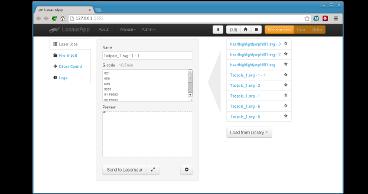

• Compatibility with the LasaurApp software (web based frontend)

• SVG & DXF Import (via LasaurApp interface)

• Multiple passes configurable from frontend as one batch

Please check the Spec Sheet for connector compatibility.

The board enumerates as a standard USB ACM Device (Serial Port) and accepts GCode commands.

LasaurApp is Python based and should run cross platform. I have tested it on Windows (XP, 7) and Linux (Desktop and BeagleBone).

You will need Python 2.7 and PIL installed if running from source.

My modified version of LasaurApp: https://github.com/art103/LasaurApp

Windows Binary Package (inc. USB Driver): LasaurApp.zip

The voltages inside the Laser Engraver are lethal (240 VAC and 25,000 VDC are present). If you don't know what you are doing, please seek professional advice.

DISCLAIMER. THE PRODUCTS AND KITS MAY BE USED BY ANY USERS, AT THEIR OWN RISK. TO THE FULLEST EXTENT PERMISSIBLE BY THE APPLICABLE LAW, WE HEREBY DISCLAIM ANY AND ALL RESPONSIBILITY, RISK, LIABILITY AND DAMAGES ARISING OUT OF DEATH OR PERSONAL INJURY RESULTING FROM ASSEMBLY, OR OPERATION OF OUR PRODUCTS. BY PURCHASING, AND USING OUR PRODUCTS YOU HAVE AGREED TO THE ABOVE TERMS IN THIS DISCLAIMER.

The laser engraver did not come with any safety mechanisms. You can happily open the PSU, Laser and Workspace doors and it will carry on Lasing.

I added some micro-switches that will power off the Laser and stop the stepper motors when either of the doors are opened. The machine will resume where it left off when the doors are closed.

I have added support for an optional temperature sensor that pauses if the coolant temperature exceeds 20 °C.

Not very elegant yet, I have used a TB6560 v2 controller board and a TI Stellaris Launchpad MCU board as my embedded controller.

The code and pin-configuration are available on GitHub: https://github.com/art103/LasaurGrbl

The opto-isolators were extremely slow and limited the maximum head speed. Even after removing them, the performance was not great. This prototype laid the way to the custom board now available.

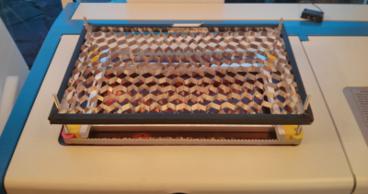

Quite frankly the "Bed" supplied with the machine was terrible. I created a pulley based adjustable cutting bed that is driven by a small geared motor, 4 pulleys and a belt.

Sketchup design here: Bed_Model.skp

The corners and pulleys are 3D printed, there are some standard bearings, threaded rod and a bit of 'U' section aluminium and PVC from B&Q.

I added support for an analogue joystick and a laser cross-hair to enable me to locate the top corner of a workpiece. This then sets the (0,0) position in the firmware (temporarily!).

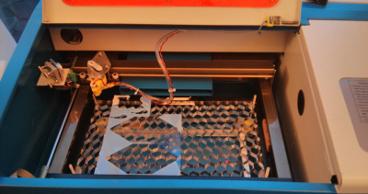

So this is it - my converted Laser Engraver.

I have uploaded a video showing the cross-hair origin setting, and a test cut to YouTube: http://youtu.be/9TBgzcda1J8

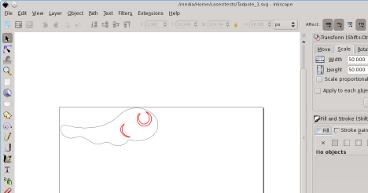

I am currently using .svg as the source format, going through Inkscape first to make sure it is sensible, then feeding into the Lasersaur frontend.

I really like this frontend. It takes an .svg (or .dxf) file as input, presents it to you in an import wizard where you can specify different passes (power and speed) for different colours of path.

See http://labs.nortd.com/lasersaur/ for more information on the Lasersaur project.

This is a photo of the test cut that I made. It is 35mm long, cut out of 3mm Perspex.

(My Daughter is learning about tadpoles at school...)

This is finally a cut that is a step towards something useful.

I want to make Lasercut cases, so a 25mm cube is a good start. The first cut had the wrong tolerance, second go isn't bad :)

This is what I've been aiming for - the resolution is (intentionally) low to reduce rastering time. Processed directly from .svg using only the LasaurApp frontend with one "Send to LaserSaur" click.

It is a 40mmx45mm Tux Penguin Engraved and Cut from 3mm Acrylic.

Code is here: https://github.com/art103/LasaurApp.git

Here are some examples of what can be achieved with my new conversion board and Lasersaur software.

The raster, vector engrave and vector cut operations are done in one session at varying power levels.

The slate piece is approximately 70mm wide.

| Command | Params | Description |

|---|---|---|

| F | - | Set the feedrate (mm/min) |

| S | - | Set the laser intensity (PWM 0-255) |

| M3 | S | Set Laser PPI (pulses per inch) |

| M4 | S | Set Laser PPI (pulses per inch) |

| M5 | - | Disable PPI (Set to 0) |

| M17 | - | Wake up steppers |

| M18 | - | Stop steppers (requires reset (“~”) to resume) |

| M80 | - | Enable Air Assist |

| M81 | - | Disable Air Assist |

| M82 | - | Enable Aux1 |

| M83 | - | Disable Aux1 |

| M105 | - | Read temperature(s) (required for pronterface compatibility) |

| M106 | - | Enable Air Assist (RepRap fan setting) |

| M107 | - | Disable Air Assist (RepRap fan setting) |

| M114 | - | Read current position |

| M204 | S | Set acceleration (mm/s/s) |

| Command | Params | Description |

|---|---|---|

| G00 | X,Y,Z,F | Seek to location |

| G01 | X,Y,Z,F,S | Feed (cut) to location (F=feedrate, S=PWM 0-255) |

| G04 | P | Dwell for P seconds (not enabled!) |

| G08 | X,Y,Z,N,F,P | Raster Extension |

| G10 | L | Set coordinate offset (L2, with X,Y,Z. L20 uses current position) |

| G20 | - | Set units to Inches (in) |

| G21 | - | Set units to Millimeters (mm) |

| G28 | - | Run Home Cycle |

| G30 | - | Run Home Cycle |

| G54 | - | Select offset bank 0 |

| G55 | - | Select offset bank 1 |

| G90 | - | Set absolute mode |

| G91 | - | Set relative mode |

Copyright 2009 by Your Inspiration Web

YIWMinimal - clean & cool projects template - Download this theme for free!